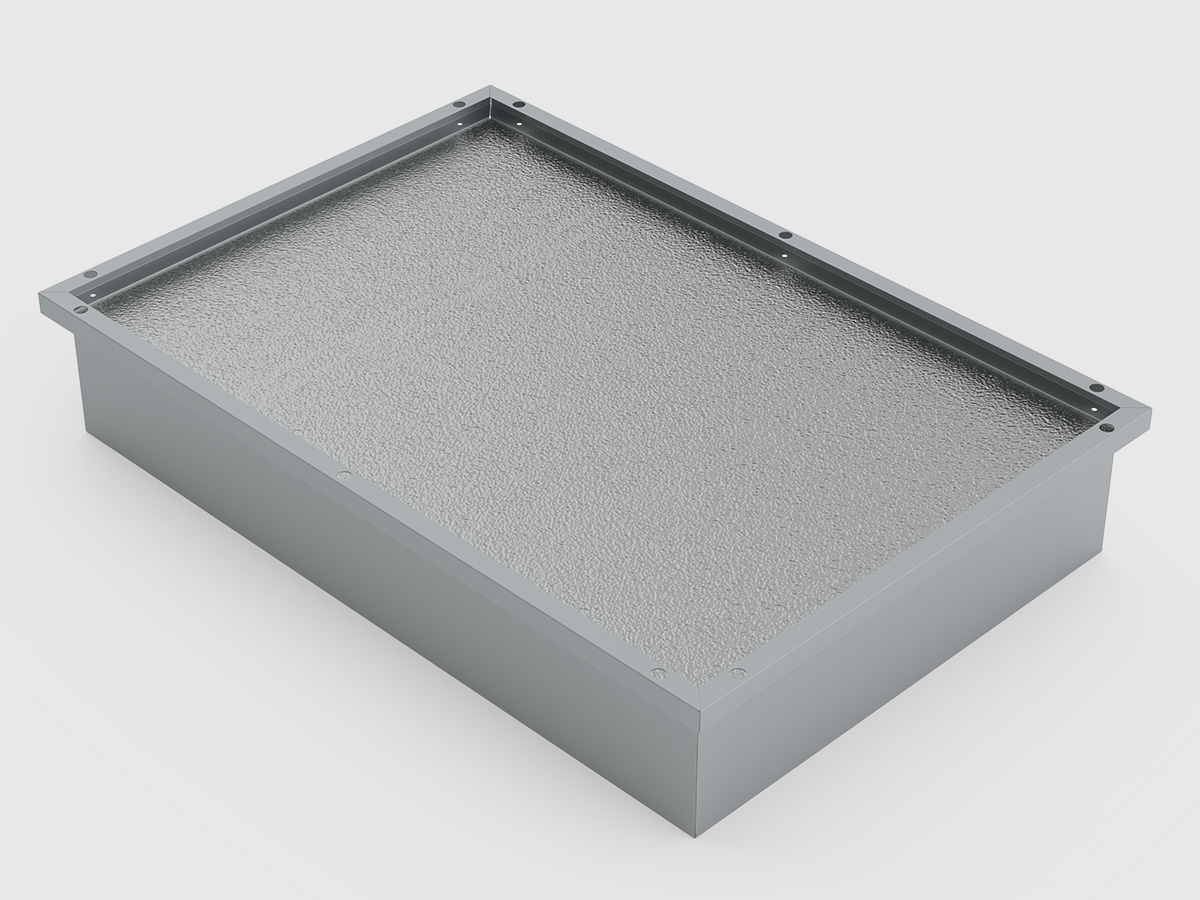

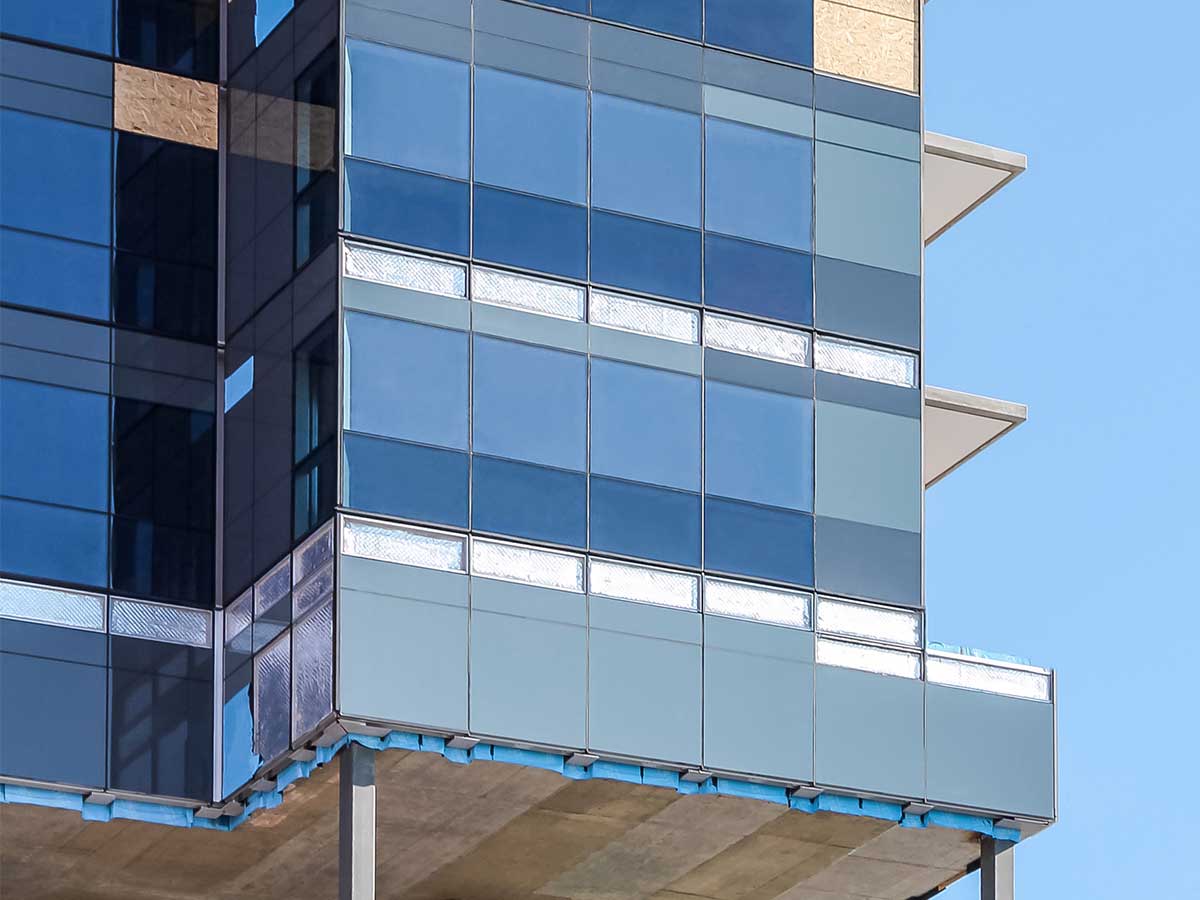

Automated efficiency takes EnvaTherm® insulated back pans and curtain-wall engineering to a new level. Innovation in foam delivery technology yields soft, even, self-sealing insulation that provides a competitive R-value for consistent, real-world performance. Unlike fibrous insulation, the insulation forms a self-sealing bond to the metal back pan shell so there is no risk of shifting/sagging or convective looping.

EnvaTherm

ENVATHERM - INSULATED BACK PANS

FOAM DELIVERY TECHNOLOGY - CERTIFIED AIR BARRIER

EnvaTherm® insulated back pans are used in curtain wall systems in conjunction with opaque glass panels or architectural metal panels for areas that do not require transparent glass.

FEATURES

-

- Local & fully certified manufacturing process;

- Fire-tested (CAN/ULC S134) for multi-storey non-combustible construction. See the full fire test here;

- Pre- and post-consumer recycled content;

- No VOC’s, foam insulation is 100% water-blown;

- Will not sustain mold growth;

- Up to 50% lighter than competing products;

- Lean manufacturing and precision equipment reduce waste and lead times.

CERTIFICATES

-

- Constructed in accordance with Intertek Design Listing LEI-IMWP 25-01

- Spec. ID 28934

- Inspections four times a year

THE AIR SEAL & ADHESION CAPABILITIES

-

- Factory-applied low-density foam insulation which prevents heat drumming and whistling

- Insulated for both air and water.

- No loss of thermal performance due to convective looping.

- Certified air barrier material ASTM E 2178-03 Intertek Project 3181312

ENVATHERM’S LOW WEIGHT AND HANDLING

-

- Commonly described as “light as air”

- In combination with our panels, they are up to 50% lighter than competitive fibrous products

- More cost-effective for handling, shipping, and installation

WASTE & ENVIRONMENTAL CONSIDERATION

-

- Pre and post-consumer recycled metal components.

- Foam is 100% water-blown, uses no synthetic blowing agents or synthetic blowing agents, and is PBDE free

- Near 100% utilization of of on-site materials

- Safe and stable after curing

- Will not support growth of mold (ASTM C1338 (2008) Standard Test Method for Determining Fungi Resistance of Insulation Materials and Facings, Intertek Canadian Project Number G100033767)